What We Do

- Home

- What We Do

PRESSURE DIE CASTING ZINC ALLOY

We manufacture wide range of zinc alloy die casting parts like cabinet handle , pipe fittings , hydraulic valve , electrical components like motor sensor cover , electric switch etc. we have more then 12 years of experience in field. we provide complete solution from die design to die making to production with suitable grade to machining.

we are manufacturing aluminum die cast parts from last 10 years. we specialize in core die blocks & parts which are critical & small we products range include motor body , hardware fittings , kitchenware appliances again we provide complete solution from die design to die making to production with suitable grade to machining & finishing.

- High dimensional accuracy

- Excellent surface finish

- Thin walls possible (1–3 mm)

- High production rate

- Minimal machining required

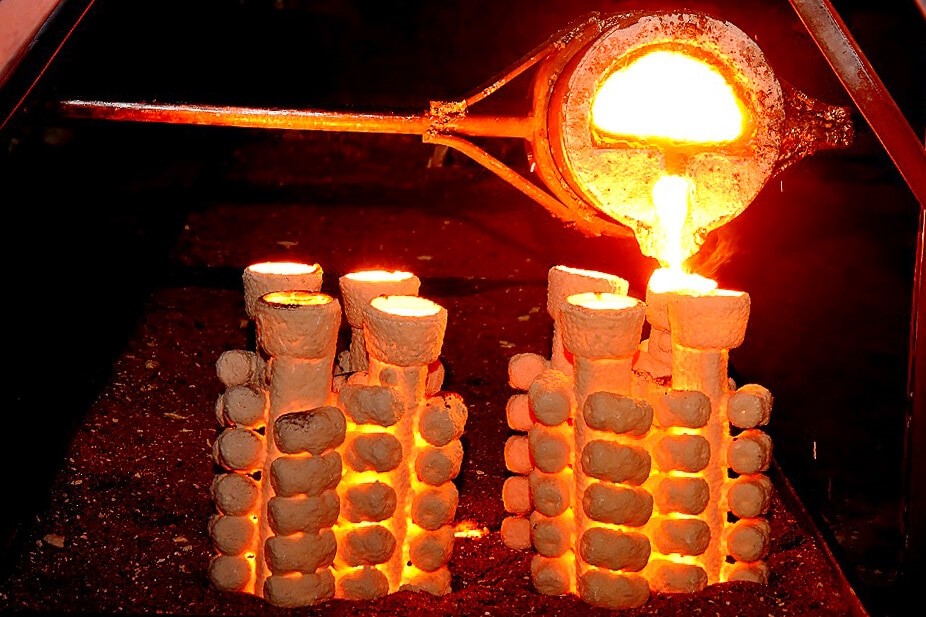

INVESTMENT CASTING LOST WAX CASTING

We manufacture high quality precision casting parts of steel & brass alloys for General Engineering as well as a wide range of Plumbing & Fitting Hardware parts. We have complete in-house production facility from metal testing to machining; we produce up to 600 metric ton annually.

- High dimensional accuracy

- Excellent surface finish

- Complex shapes made easily

- Wide material flexibility

- No parting lines

- Good mechanical properties

GRAVITY CASTING

Gravity casting is a metal casting process where molten metal flows into a mould using only gravity—no external pressure or vacuum is applied. We are manufacturing many complex aluminium parts through gravity casting up to 8 kg.

- Better surface finish than sand casting

- Good dimensional accuracy

- Lower tooling cost compared to pressure die casting

- Stronger parts due to slower, controlled cooling

Serving Multiple Industries

From zinc and aluminum castings to precision machining, heat treatment, and assembly – we offer complete solutions for your metal component needs.